As water cooled thermoelectrics clouds chambers reached a limit in term of efficiency of cooling, it was time to try another technology : phase change. The scientific projects I have done over the past 10 years have allowed me to control this technology after only a few years of research. A phase change cloud chamber works « basically » like a refrigerator. The manufacture of such a chamber requires heavy materials and advanced knowledge to make a machine that will be as reliable as the fridge of grandmother who is 20 years old and still working.

I have built around twenty phase change system iterations to find the appropriate parameters to have a machine capable of displaying particles with a maximum quality of viewing. It’s « easy » to obtain particles in a cloud chamber. All you need is the right negative temperature (-25°C threshold), a sealed chamber of moderate height and some electrical field. The most difficult part which can take ages of tweaking is to find the maximum quality of tracks, allowed by a Langsdorf design.

This intrinsic quality is defined for each tracks by :

-

- a strong density of droplets (poor density leads to difficulty of viewing),

- a minimum diffusion of the primary ions (high diffusion gives spread tracks),

- an absence of movement of gas turbulence (turbulences distort tracks and false the interpretation of the event).

Dimensions of the chamber, position and rate of evaporation of alcohol, management of the condensed alcohol, geometrie and strength of electric field, gradients of temperature (vertical + horizontal), walls and ground effects are some of the parameters which influe directly the tracks quality. The historic pictures taken by expansion cloud chambers until 1950, that you will find in this site, all shows a perfect quality of tracks

What’s the point to build a phase change system which need considerable effort, if it’s to obtain a poor seeing of events ? that’s the problematic of many clouds chambers in the world. They displays tracks of particles, but the quality of them is often average and most people are satisfied with that. A cloud chamber remain a scientific experiment used to apprehend the basics of nuclear physics. To have a true picture of the nuclear events the seeing should not be perturbed with a construction where the optimal parameters are not reach.

I can not give you the details of the construction of my phase change clouds chambers, because I spent too many years to build them, but the next photos will show you some old projects.

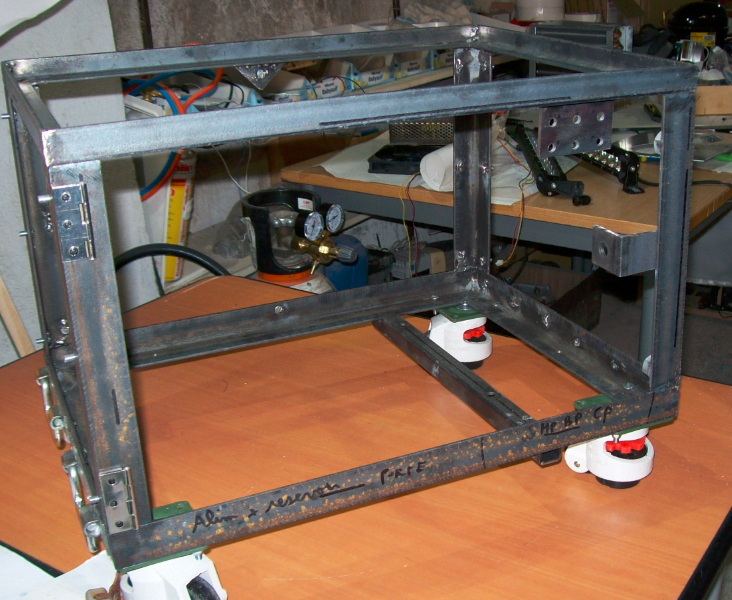

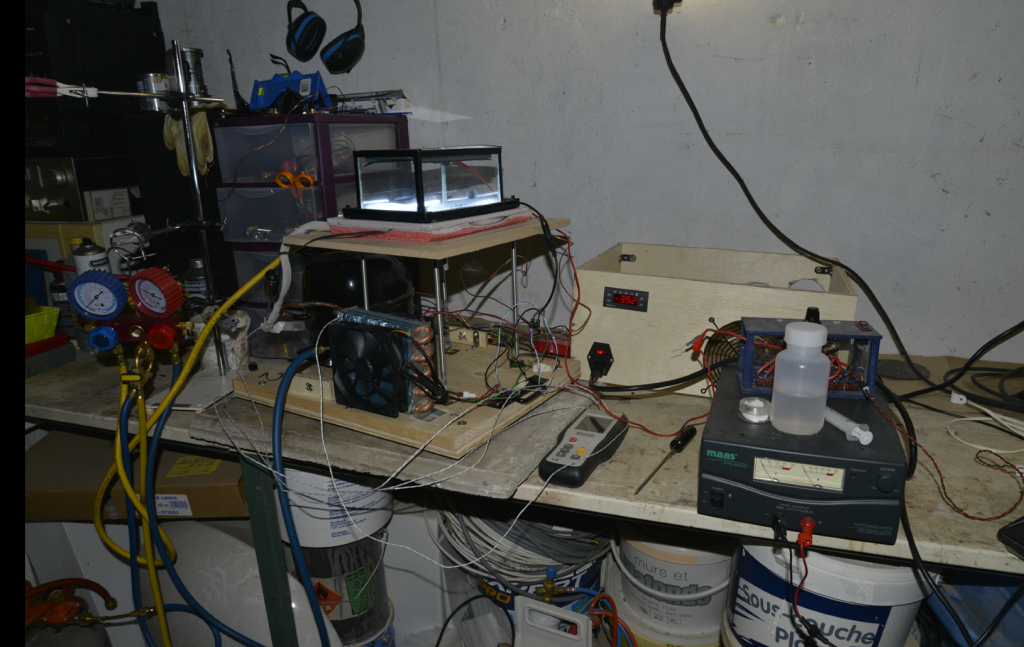

First attempts The first step were to identify what cooling power is needed and how to build it with the proper material.

As we can build big surface cooled uniformly at about -40°C with phase change system, the conditions of equilibrium are modified versus thin volumes of thermoelectrics clouds chambers. So the parameters which leads to a stable equilibrium are not easily found.

As we can build big surface cooled uniformly at about -40°C with phase change system, the conditions of equilibrium are modified versus thin volumes of thermoelectrics clouds chambers. So the parameters which leads to a stable equilibrium are not easily found.

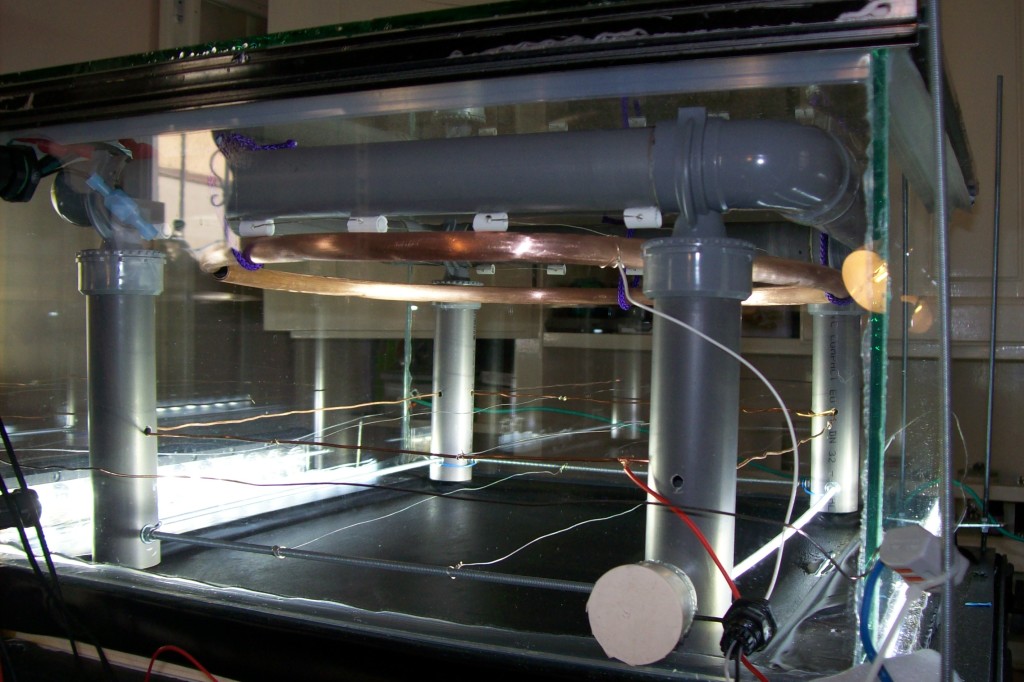

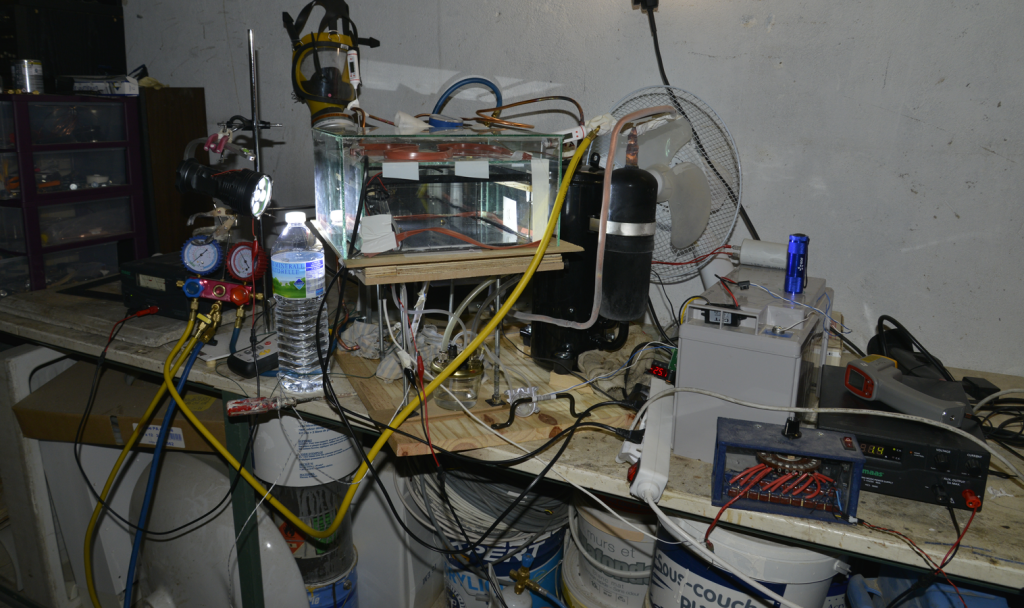

The next pictures shows the tests for different volume of chamber and alcohol container.

The next pictures shows the tests for different volume of chamber and alcohol container.

Despite the awful build, some particles were visible. The sensible layer was very thick.

hj

I started my first attempts in phase change in early 2014. This previous « all in one » wood machine, worked nicely. This video was published 2 years after the beginning. The active surface was 40 x 25 cm.

I started my first attempts in phase change in early 2014. This previous « all in one » wood machine, worked nicely. This video was published 2 years after the beginning. The active surface was 40 x 25 cm.

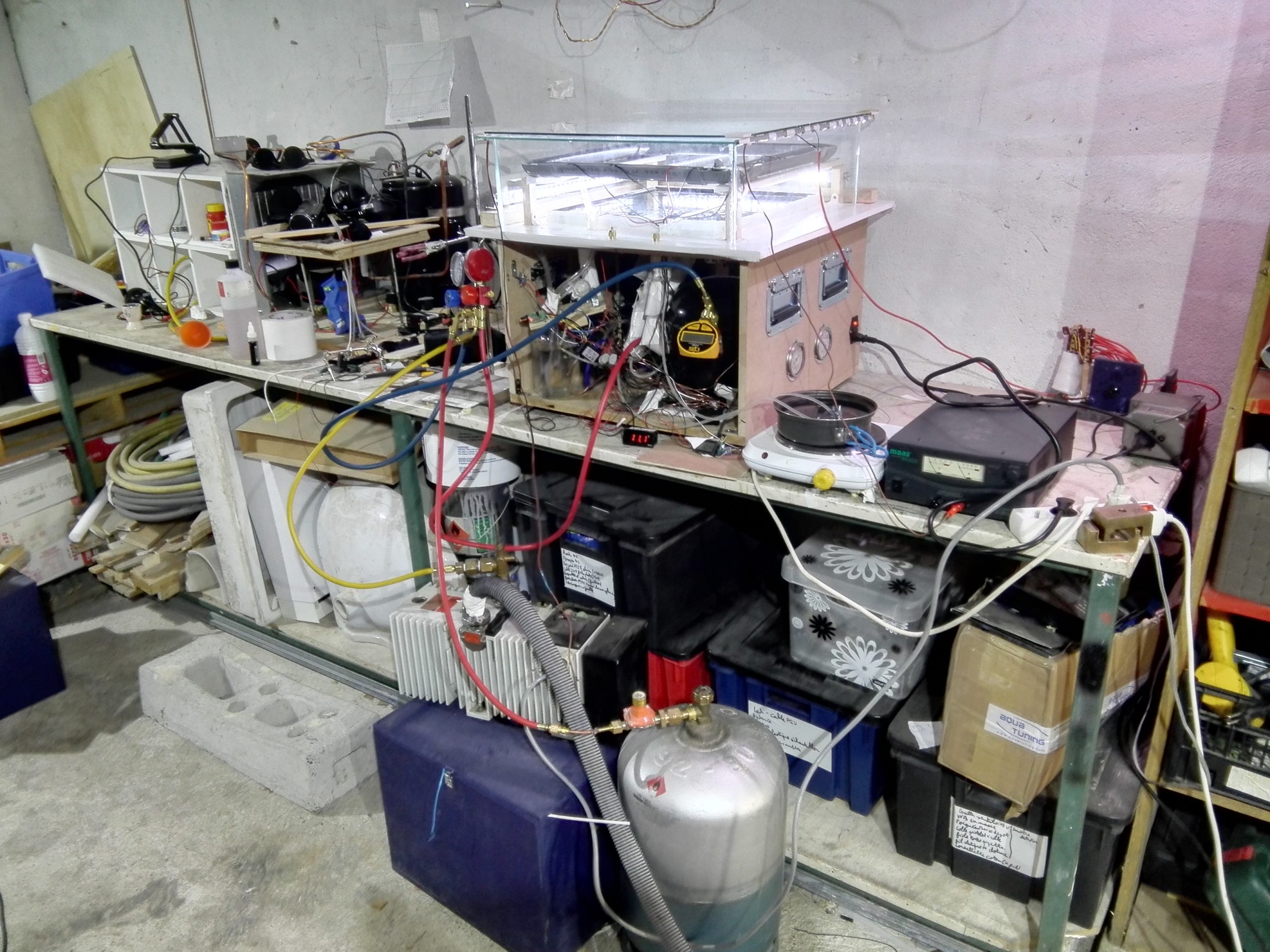

First build

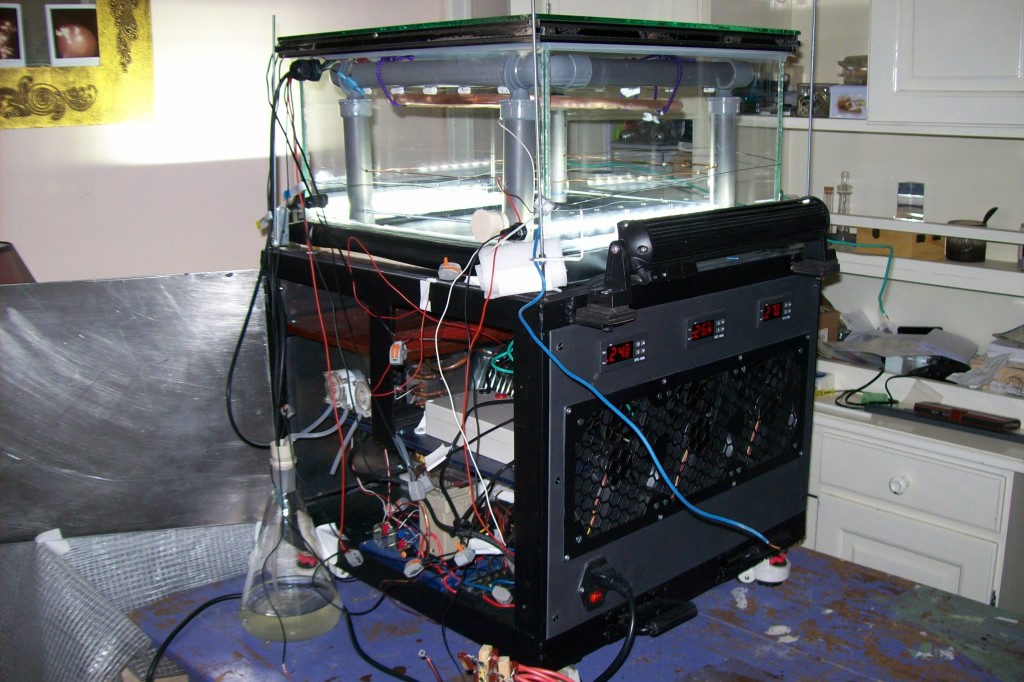

Wood have a good rigidity and is a cheap material, but phase change machine are heavy (the compressor itself weigh about 20 kg). So a steel frame is needed to have a robust build (which increase also the overall weight). This machine served as bench test to study different dimensions of chambers, the effect of electric field and a system of recovery of the condensed alcohol on the main plate. This machine could works for hours and the active surface was 32 x 32 cm. The surface was lower than the previous model because I wanted to build something less huge to transport.

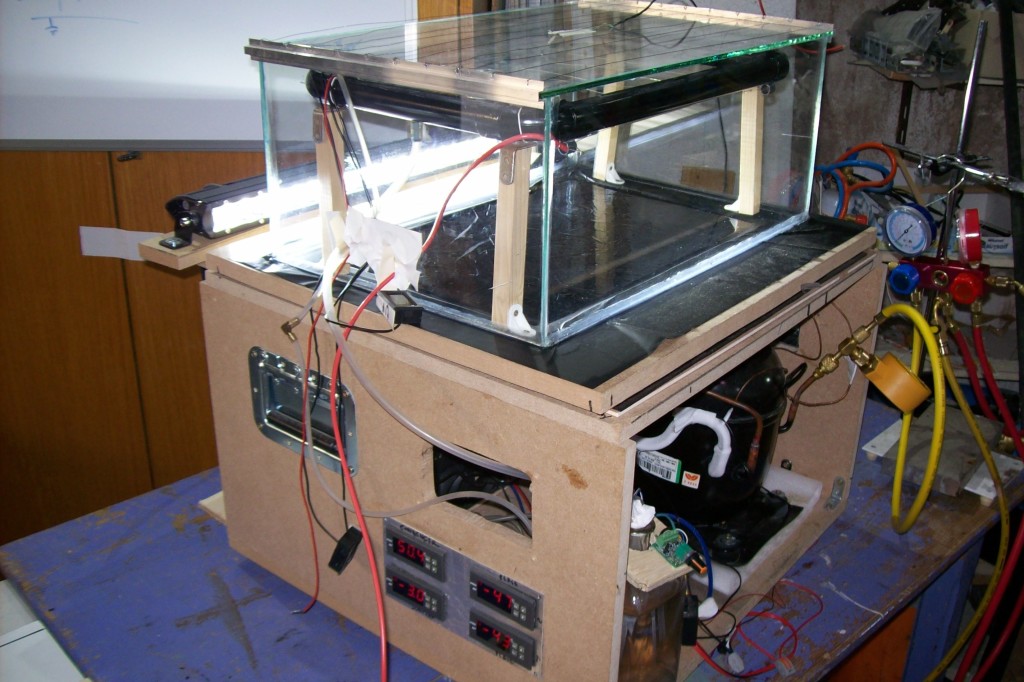

Second build

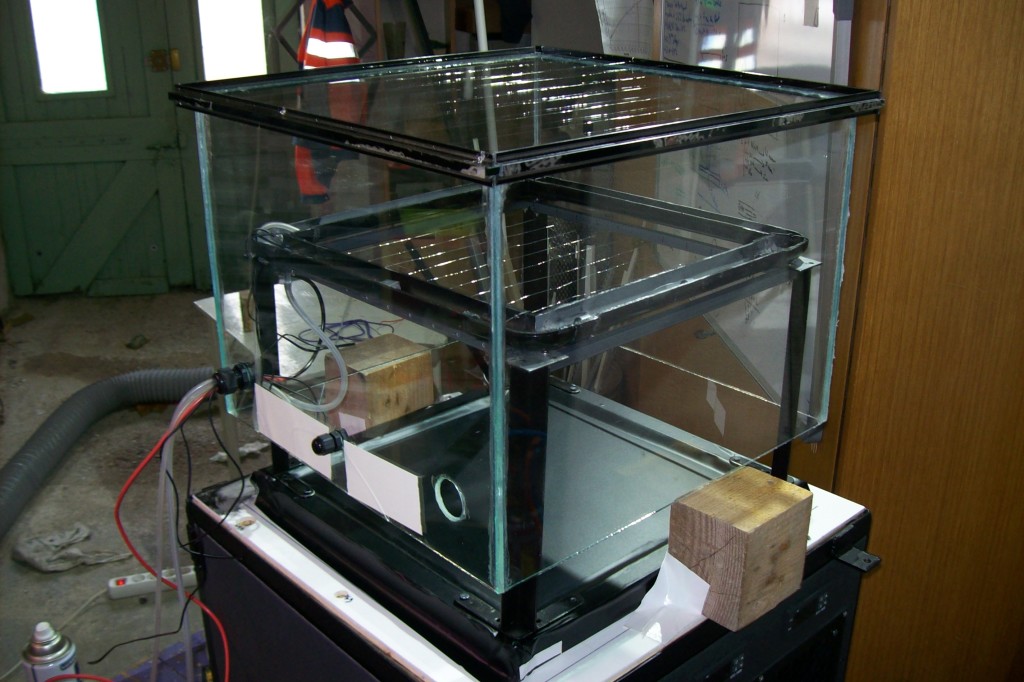

I wanted something more portable than the first build, so this time I choose a tinier active surface : 32 x 18 cm. I calculated that’s the minimum surface for a phase change system. This give a machine of 35 x 47 cm at ground.

The height is about 60 cm including wheels (the 1,5 L water bottle give the scale). Weigh is about 30-35 kg but I’m working on this to reduce weight. It works for a dozen hours without assistance, and the machine display particles about 20 to 30 min after power up. This one contain a large NdFeB magnet which deflect light particles. This machine need some works to improve the design and to simplify the functioning.

The machine of 2020/2021

I made a complete new cloud chamber during the Covid events in April 2020. I didn’t have access to new materials so I made it from scratch parts so the aesthetic could be slightly better. Here is a picture :

The weight is about 25 kg. The active surface is ~40 x 20 cm. The dimensions of the whole machine are 45 x 55 cm (including lights), with a total height of 42 cm.

Here is a video showing the machine in action (recorded 2 months after its build) :

I made some crash tests during May-December 2020 then early 2021 I simplified the chamber. Only the glass container was modified (way to evaporate alcohol, height of the chamber, layout of the electric field and light, recovery of the condensed alcohol…). The latest version of the machine is below. This video will show you how to operate it. The equilibrium is reached 8-10 min after powering up the machine.

I’m very satisfied about the quality of the tracks and the reliability mainly because it can work in cold or hot temperature rooms. The main drawback is that the infrared light is needed during the operation (it don’t disturb the visibility of the particles for the viewers). I made other constructions which don’t need this thermal source, but the quality of seeing is not as good as with the thermal lamp. I can use a fan heater to warm the top surface but this produce an additional loud. So I decided to keep the silent thermal IR lamp in my next designs. If you remove the IR light, the machine will work with no change during a dozen of minutes, then some mist will form on the top and will deteriorate the equilibrium.

I don’t have much modifications left to do. What the next version will need is better connectors, security, cables managements, design….

I’m currently working about the CE marking to have the right to sell this machine on European market. This step is almost completed, I wrote all the documentations needed for that.

A radium hand in the cloud chamber